Thehigh polymer mattress & cushion & pillow production line is a new flagship product developed by Qingdao Julide Machinery Co., Ltd. in recent years. This production line equipment is used to produce polymer air fiber mattresses, cushions, pillows and other series of air fiber products. The production mainly uses POE polyolefin elastomer, no formaldehyde, no glue, no contact winding method, three-dimensional mesh type The structure is intertwined and integrated in water. At present, the product is widely used in nursing homes, hospitals, etc. as nursing mattresses, dry and breathable, without bedsores, used in kindergarten and school dormitory mattresses, pet mats and home tatami mats, etc., completely washed, highly elastic and comfortable, and gradually replace the traditional interior The core material is popular among consumers.

The polymer mattress cushion pillow production line produced by Qingdao Julide Machinery Co., Ltd. has successfully passed the EU CE certification and ISO quality system certification. The products have the following advantages:

Adopting a new generation of "O" type spinneret: The previous generation of spinneret adopts a "C" type wire ejection structure, which will cause cracks when spinning, resulting in unstable product properties. Our company concentrates technical strength and after repeated tests, Developed a new type of "O" type spinneret, which solved the long-troubled industrial technical problems.

Automatic water tank forming machine: The operation of the previous generation product is quite complicated when the water tank is towed. After improvement, the automatic tablet pressing device is added, which greatly reduces the water tank towing operation, and the operation is more convenient and the production is more stable.

Fully automatic stacking device: Compared with the previous generation of oblique stacking racks, the new generation of production line adopts servo-controlled stacking devices, adding a human-machine interactive visual touch screen operation interface, which is easy to operate and does not require a lot of manpower.

High-quality electrical components: ABB frequency conversion control greatly saves the energy consumption of the production line. Compared with ordinary AC production lines, it can save energy by more than 30%. ABB's high stability is also one of the advantages of this production line; Schneider contactor, French industrial pioneer enterprise, top electrician in the world Enterprise, high-quality electrical components ensure the efficient and stable operation of this production line; Siemens PLC controller is reliable, easy to operate, and flexible, and has excellent performance in different environments.

Adopt servo control system: The conveyor and stacking device of this production line adopt the servo control system, which makes the operation of the whole machine energy-saving and efficient.

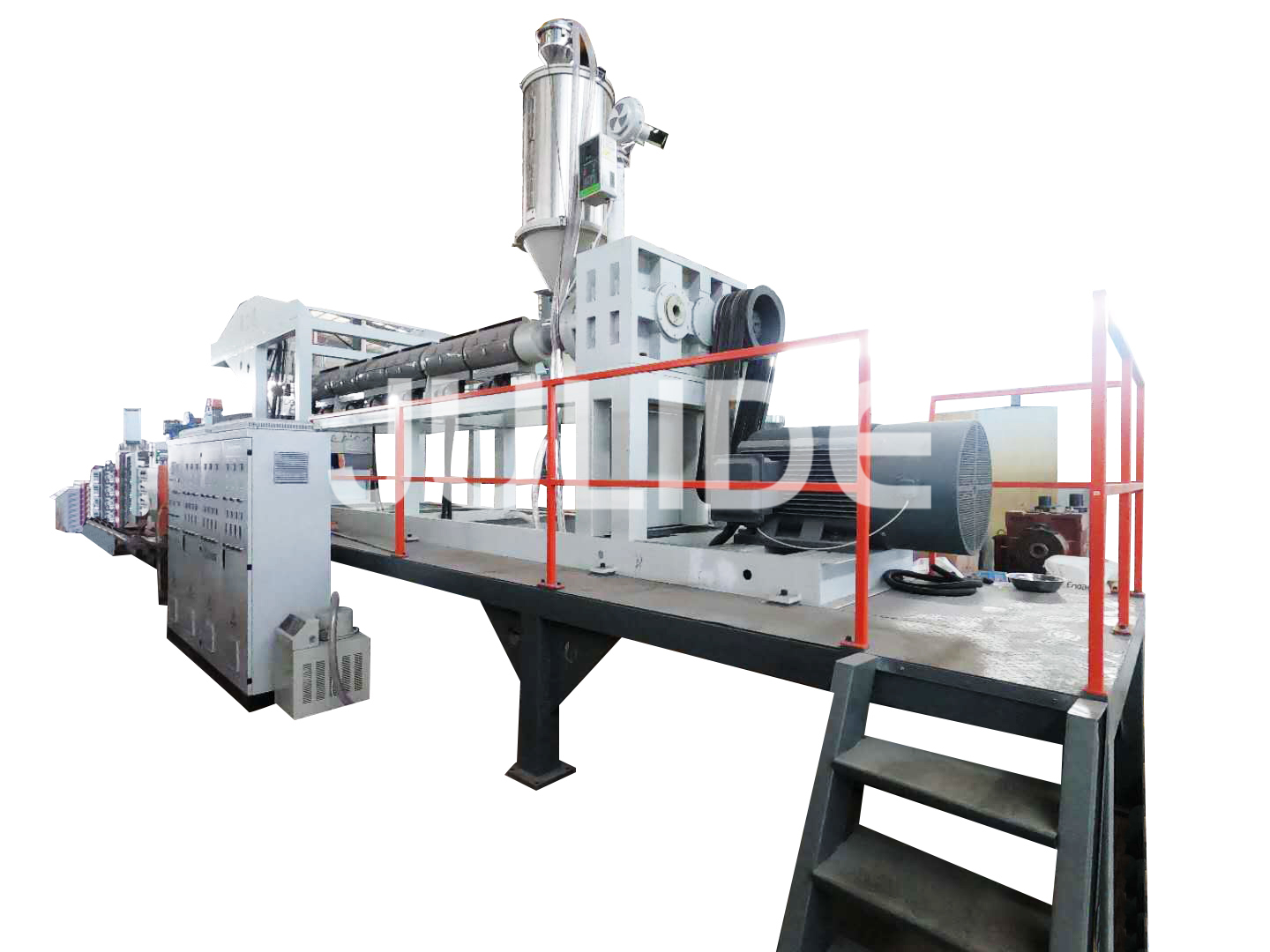

|

EXTRUDER MODEL

|

PRODUCT WIDTH

|

PRODUCT THICKNESS

|

MAIN MOTOR POWER

|

INSTALLED CAPACITY

|

MACHINE OUTSIZE

|

|

SJ120/33

|

1500

|

1-10cm

|

132kw

|

228kw

|

24x3.5x4m

|

|

SJ150/33

|

2000

|

1-20cm

|

160kw

|

280kw

|

27x4x4.2m

|

。